Your ideas, delivered.

Full Service R&D and Fabrication

Working with Vactronix is easy. We offer a complete suite of capabilities that allow customers to quickly maximize our unique material and process capabilities via contracted R&D efforts. Throughout development, we work to transition the customer to a highly scalable and repeatable component manufacturing that enhances value. The following is a basic overview of standard services and capabilities we can offer your team.

Vactronix Core Technology Areas

Physical Vapor Deposition (PVD)

Next generation devices need next generation materials. Vactronix’s proprietary high-energy 3D PVD technology delivers materials with dramatically higher performance in every category. Scalable. Repeatable. Cost-Effective. Flexible. Superior.

Component Processing

Vactronix utilizes the latest “cutting-edge” femtosecond lasers and adds its own proprietary technology to hold the tightest tolerances in the industry. Because deposition occurs on a stable substrate, we routinely hold and easily validate to single digit micron scale specifications. We love complicated.

Engineered Surfaces

When you can control surface heterogeneities to this level, devices are begging for unique engineered surface topologies. With a full suite of ablation, chemical and lithography capabilities in house, your imagination is the only limitation.

Rapid Development Toolbox

PVD Material Fabrication by High Energy 3D Deposition

Target and substrate preparation

Tubular and custom net shape chamber configurations

PVD sputtering of binary Nitinol (per ASTM-F2063 & F-2633) and ternary Nitinol alloys, plus other metallic materials

Novel Alloy Development

In-situ alloying during PVD

Radioopaque ternary alloys and coatings

can work beyond the limitations of foundry based process

Overnight rapid iterations driven by characterization

Dramatically lower cost

Material Characterization Capabilities

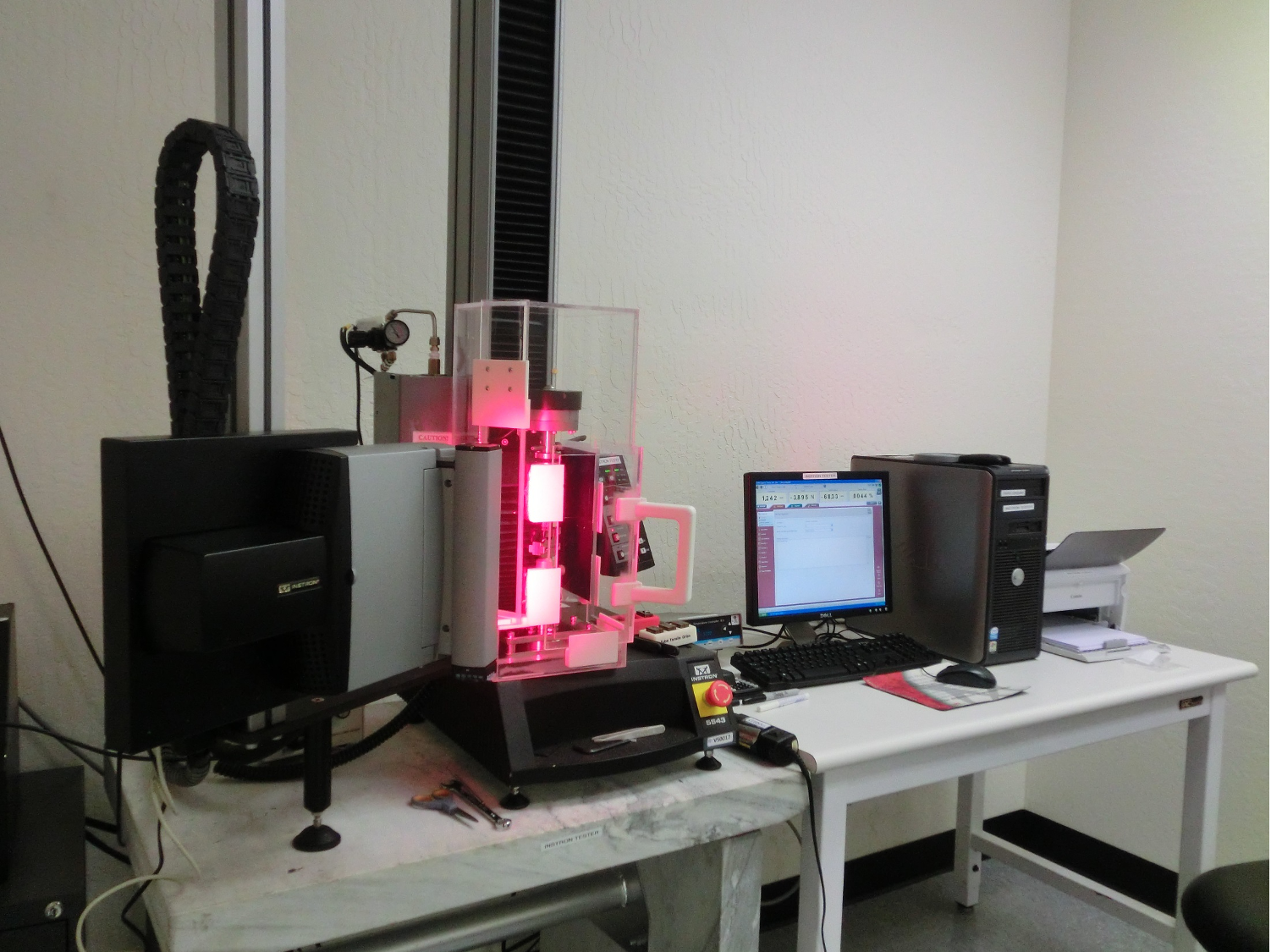

Tensile mechanical properties (per ASTM F-2516 with thermal chamber)

Transformation Temperture by BFR (per ASTM F-2182) or DSC (per ASTM F-2004)

Metallurgical preparation and analysis - diamond saw, polisher, potting apparatus

FE-SEM with SED, BSED, & EDS

3D optical imaging up to 1000x magnification

Surface characterization and engineered surface treatment

Patented engineered surface technologies

Optical interferometer for surface roughness and film thickness

Sessile drop surface tension measurement

Potentiodynamic corrosion testing per ASTM F-2129

Precision Measurements

Precision, micron-scale dimensional measurement by optical microscopy

0.1µm resolution drop gage

5-axis automated stent measurement

Micro-CT with sub-micron voxel resolution

Laser micrometers

Device Fabrication

2-axis laser ablation

Heat treatment or shape-setting up to 1250°F/677°C and up to 16"x30"

Polymer and metallic coatings

Electropolishing

Chemical passivation

Device Testing

Flow model with blood analog

Catheter push force measurement

Iris crimpers/loaders - several

Radial force measurement up to 120mm length x 16mm diameter

Equipment Design & Build

Mechanical, electrical, and software engineering

Partial machine shop

Device Design/Optimization Assistance

Mechanical design and FEA (finite element analysis)

Rapid prototyping including latest generation FDM 3D printers

Quality Management System

Electronic document control and quality management system

QAD MRP (manufacturing resource planning) system

ISO 13485:2016 registration through BSI

Quality policy from QSM-00001

*BSI certificate for reference only, please contact Vactronix directly for current copy.

Words we live by.

“Vactronix Scientific LLC is a material science company with a mature technology platform that changes the way implantable prosthetic devices are fabricated and ultimately assimilated by the human body. The company’s initial products are focused on intravascular stent technology with future product potential in orthopedic, cosmetic and other medical specialties, or non-medical products that may benefit from the Company’s technology platform.

Through innovation, teamwork and operational excellence, Vactronix Scientific is committed to delivering the highest quality medical devices that meet or exceed customer expectations.”

— Vactronix Scientific Quality Statement

The Company and its employees are committed to the following quality principles:

· Quality is Customer-focused—we will provide superior products and services that customers (within and outside our company) want and that consistently provide value that customers expect.

· Quality is Prevention—we will work together and with our suppliers and our customers to design and maintain excellence in our products and business processes.

· Quality is QMS Effectiveness—we will evaluate our effectiveness in who we are and what we do, making our efforts easier and their results better.

· Quality is Timely– we are committed to maintaining compliance with ISO and FDA standards and to responding to any changes in those regulations in a timely fashion.

· Quality is Scalable– we are committed to inventing novel, disruptive technologies as well as ensuring that these technologies are scalable, repeatable, and cost effective. These qualities are necessary for adoption of our new technologies.”

Ready to start?

We are ready when you are. Contact us to start the process. We usually begin by on-boarding your team with a technology overview and can begin assigning resources to your project immediately. There’s no time to waste.

Review our Terms & Conditions.